- Portfolio

- Product

Portfolio

Back

Spark® Top II

The art of sealing sparkling wines

*Carbon Footprint of natural cork stoppers, excluding NDtech® process, for standard product. For more information, please access our Carbon Footprint certificates.

*Carbon Footprint of natural cork stoppers, excluding NDtech® process, for standard product. For more information, please access our Carbon Footprint certificates.

Excellent mechanical behavior

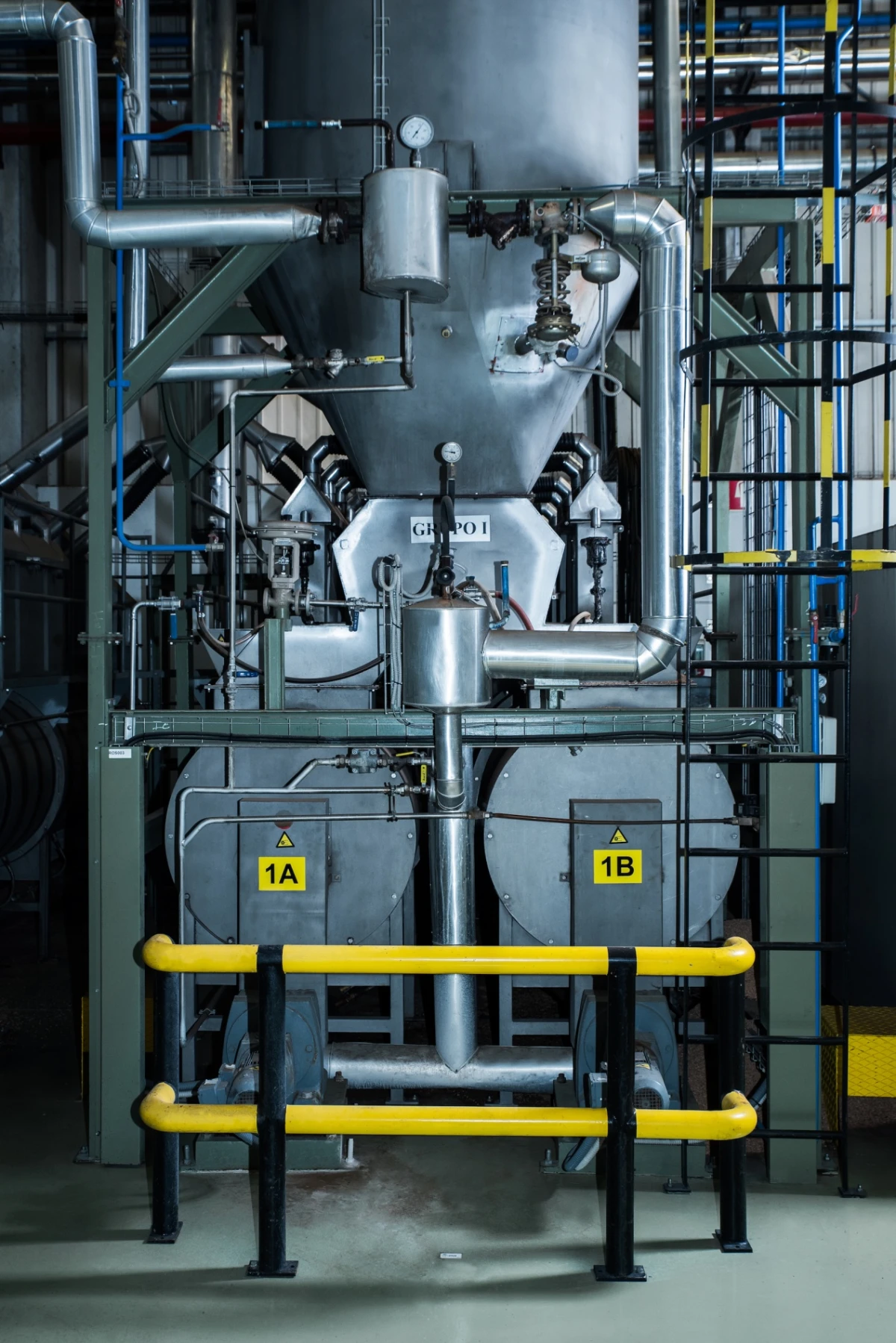

The Spark® Top II stopper benefits from technological processes that ensure the best sensory performance. ROSA and FBT for the cork granules and CorkNova for the discs guarantee a stopper with excellent performance, offering the best results in terms of pressure resistance and preservation of the wine's aromatic quality.

The discs used also benefit from X-ray mass analysis control, which contributes to their physical and mechanical performance.

Spark® Top II is the cork preferred by most winemakers, offering the best compromise between physical and mechanical performance, aesthetics and sensory characteristics.

Cork Properties

| Tests | Characteristics | Specifications |

|---|---|---|

| Physical-Mechanical | Length (I) | l ± 0.5 mm |

| Diameter (d) | d ± 0.3 mm | |

| Granules size | 3 - 7 mm | |

| Torsion angle | ≥ 40º | |

| Ovalisation | ≤ 0.3 mm | |

| Moisture | 4% - 9% | |

| Torsion moment | ≥ 40 daN.cm | |

| Dust content | ≤ 1 mg/ stopper | |

| 2-Discs thickness | ≥ 10 mm | |

| Average weight | X ± 1 gr | |

| Specific weight | 230 - 290 Kg/m3 | |

| Pressure resistance | ≤ 6 bar | |

| SPME GC / MS / ECD | 2, 4, 6 - Trichloroanisol (TCA) | 99% ≤0.5 ng/L and 1% ≤1 ng/L* |

| CO2 Footprint |

|

-54.61 g/stopper |

*2, 4, 6 –Trichloroanisol (TCA) - Releasable TCA content of 99% at or below the 0.5 ng/L quantification limit and 1% at ≤ 1.0 ng/l, conducted in accordance with ISO 20752.

- 47 x 29.5 mm

- 48 x 29.5 mm

- 48 x 30.5 mm

- 48 x 31 mm

- Amorim can calculate the required cork diameter by studying the internal profile of the bottleneck, the characteristics of the wine and the corking conditions.

- Order your cork stoppers for immediate or short-term use. Ideally, these cork stoppers should be used within four months of the date of manufacture if the storage conditions are respected.

- Store the cork stoppers in their original packages, in a well-ventilated room with controlled temperature between 15°C and 25°C and 50% to 70% humidity.

- Do not leave boxes and/or bags open with surplus cork stoppers.

- Ensure any dust its removed before corking.

- Ensure the cork is compressed smoothly, to a diameter 1.5 to 2 mm smaller than the diameter of the bore of the bottle.

- Ensure insertion of the cork is as quick as possible.

- For standard bottlenecks, the cork should be inserted at 24 mm ± 2 mm from the top of the neck with the wire wood applied.

- Minimise moisture on the inside of the bottleneck.

- Don’t leave the cork stoppers in the feeder as to avoid dust.

- Always use stoppers with a surface treatment suitable for the type of beverage, bottling process and selected bottle.

- Ensure that all dust is removed using suitable placed aspiration – particularly before inserting the cork stopper.

- Maintain the corker jaws free of nicks and signs of wear.

- Ensure proper alignment of plunger and location ring.

- Ensure corking machine operates smoothly, especially during compression.

- Clean all cork-handling surfaces regularly with chlorine-free products.

- Ensure the equipment is suited to the cork and bottle used.

- After bottling, the bottles should be kept in an upright position.

- Ideal bottle storage conditions are 12–18°C at 50–70% humidity.

- Keep the wine cellar free of insects.

- Bottles should be stored and transported in an upright position for better preservation of cork recovery after extraction.

- The product must not be stored in a location exposed to sunlight, heated environment and in direct contact with the ground

All Amorim Cork, S.A. products comply with existing regulations and legislation (European and FDA - Food and Drug Administration) for products in contact with food.