- Cork and Wine

- Raw Material and Production Process

Raw Material and Industrial Process From bark to bottle

From the forest to the bottle, cork embarks on a fascinating journey in which the harmony between human beings, nature and technology are synergistically interwoven. Stripping, carried out by highly qualified workers who pass on their knowledge from generation to generation, is just the first step in an extraordinary process in which nothing is wasted.

The cork is harvested every nine years, between the months of May and August, when the tree is at its most active stage of growth. It is important to emphasise that no trees are felled during this process; the cork is extracted sustainably and carefully, without damaging the tree. With millimetre precision, the procedure involves a vertical incision, followed by a horizontal incision in the trunk, allowing the cork plank to be carefully removed. The cork oak is the only species whose bark regenerates naturally after each stripping, growing back completely and acquiring a smoother texture.

For the cork oak, each end represents a new beginning, symbolising a cycle of renewal and sustainability.

“These mighty and majestic Quercus Suber which, besides being so spectacular, silently donate the best quality of stoppers that preserve in ideal conditions our careful work as wine producers”

200 Years of Life: The Resilience of the Cork Oak

A cork oak has an average life expectancy of 200 years. After a period of 25 years, the tree can be stripped for the first time, although this initial cork, known as ‘virgin’, doesn't have the desired quality. Subsequently, it is necessary to wait another 9 years for the cycle to be completed. A number, ranging from 0 to 9, is painted on the trunk, indicating the year in which the cork was harvested. The cork cycle is both rhythmic and mysterious. Only after the third stripping - that is, approximately 43 years after the tree was planted - does the cork reach the ideal conditions for the production of natural cork stoppers.

From the cork plank to the final product, the cork goes through a series of carefully differentiated stages, depending on the type of stopper for which it is intended. However, in terms of preventative and curative care, all cork planks receive the same meticulous treatment.

The production of a cork stopper is a fascinating process, where craftsmanship is as crucial as the most advanced technology available. Despite all the evolution in the industrial process, cork stoppers are still the result of a remarkable collaboration between human beings and machines, an alliance that has lasted for centuries.

“Wine and cork are products that have emerged from nature and from the history of mankind. They have been united for centuries and have taken a long time to achieve their greatest expression.”

The Art and Science of Cork Stopper Production

Cork planks leave the forest in trucks and are placed on a yard where, for six months, it shall stabilize and develop an even moisture content. Each load is labeled and registered to trace the origin of an individual batch to the forest. Traceability is essential to obtain certification by the Forest Stewardship Council (FSC). Planks are stacked onto stainless steel structures in large concrete areas, at a slight angle, to prevent microbial contamination and maximize air circulation.

Following the resting period, planks are sorted by skilled hands who select the thicker planks - high-quality cork - to be transformed into natural cork stoppers, made of a single piece of cork. The thinner planks will be used to make disks for technical stoppers.

The next step of the industrial process is boiling. Cork planks are boiled in stainless steel tanks. The goal is to remove organic objects embedded in the pores and enable cork to reach the ideal moisture content for processing. At Amorim, an exclusive boiling process called CONVEX also captures and removes volatile organic compounds from the water. Each batch is boiled for an hour in a high technology treatment tank. When the planks are taken out, their volume has increased by 20%, making them more regular and easier to handle.

After boiling, the planks are too damp to be processed, and therefore are again stacked for stabilization in an area with good ventilation. After two days, they are ready to be processed.

The edges of the planks are prepared and the corners trimmed. Based on key characteristics like appearance, thickness and porosity the planks are separated into quality categories. Only good quality planks are selected for producing cork stoppers. Those with defects are sent to be ground and will be turned into other cork products.

The selected planks, used for top-of-the-range - natural - cork stoppers are cut into strips and punched with a machine to extract the cylindrical stoppers. This is a highly precise semi-automatic or automatic process.

The stoppers are separated mechanically and photographed by computers, which classify them based on visual quality. Many cork stoppers are rejected and will be used to make cork granulate for technical stoppers.

A statistically significant sample from each batch is subject to gas chromatography analysis, a sophisticated process that aims to detect undesirable components, namely TCA precursors.

The batches undergo treatment with ROSA Evolution, an innovative system patented by Amorim, which uses controlled steam to eliminate any trace of TCA. Each batch of stoppers is submitted for analysis, and whenever the minimum percentage of TCA is detected, it is immediately returned to the source.

Irrespective of the results of the analysis, all the stoppers in the high-quality batches are submitted to a steam distillation process.

Near the end of the process, natural stoppers are polished for a clean, smooth finish. They are then washed, dried, and stabilized. All these processes aim to minimize the risk of microbial contamination.

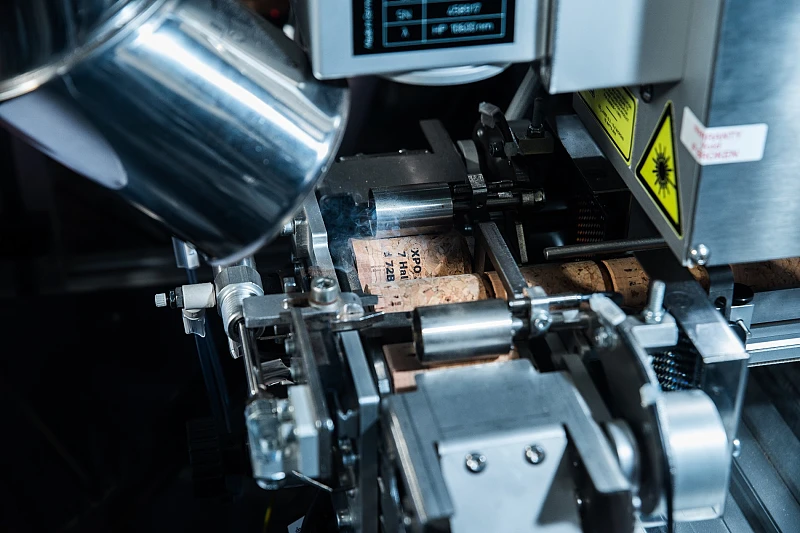

The cork stoppers are ready for the finishing touches. After confirming that they meet the client’s specifications, natural stoppers are branded, with heat, ink or laser, all approved by the Food and Drug Administration, and covered with paraffin or silicone to facilitate their insertion into and extraction from the bottle.

Finally, the batches are packed, and the packages are sealed. The cork stoppers are ready to discover the world’s finest wines.