- Media Center

- News

News Media Center

Research highlights the negative carbon footprint of Amorim’s Neutrocork®

Results of Pricewaterhousecoopers study confirm Corticeira Amorim’s commitment to the Circular Economy.

At a time when protecting the environment is more important than ever, consumers increasingly prefer cork stoppers because of their impeccable sustainability credentials, in addition to their superior technical capacities in terms of safeguarding the quality of wines. A September 2018 study produced by PricewaterhouseCoopers for Amorim & Irmãos confirmed that Amorim’s rigorous production control system guarantees excellent quality and a negative carbon footprint for its Neutrocork stoppers - a latest generation technical stopper which guarantees great structural stability.

The Neutrocork stopper is recommended for wines with a certain complexity and has been embraced by thousands of winemakers around the world.

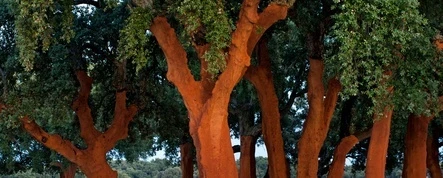

To produce Neutrocork stoppers, natural cork is sourced from cork oak forests and then sorted, boiled, ground, and treated using Amorim’s proprietary ROSA® system. The uniform-sized micro cork granule composition is then pressed into individual moulds. The 2018 PwC study adopted a Business to Business (Cradle to Gate) approach in which it calculated the carbon footprint until conclusion of the production process and distribution of stoppers to the UK.

The study’s main conclusions included the fact that the Neutrocork stopper has a positive carbon footprint - -342 kg CO2 per ton of product, corresponding to -1.8 kg CO2 per 1000 stoppers (i.e. -1.8 g CO2 per stopper).

Furthermore since production of Neutrocork stopper is integrated within the overall cork production chain, the PwC study considered the carbon sequestration of the cork oak forest associated to cork production, delivering an even higher result - corresponding to a total of -73,342 kg CO2 per ton of product -392 kg CO2 per 1000 stoppers (-392 g CO2 per stopper).

The methodology used in the study was life cycle analysis (LCA) based on the guidelines of the Greenhouse Gas Protocol (GHG), developed by the World Business Council for Sustainable Development and the World Resources Institute.

The survey was carried out taking into consideration ISO 14040 series of standards and PAS 2050: 2008 “Specification for the assessment of the life cycle greenhouse gas emissions of goods and services”.

The production stages encompassed within the Cradle to Gate methodology involved four business units of Corticeira Amorim - Amorim Florestal, Equipar, Amorim & Irmãos (De Sousa), and Amorim Distribuição.

The emissions measured in kg CO2/ton for each product were estimated using multiple data analysis sources.

The study noted that a key factor in ensuring a negative carbon footprint is the fact that the cork oak forest is a carbon sink, responsible for retaining -73 tons of CO2 per ton of cork produced, as confirmed in a recent study by the University of Aveiro (Study of the Department of Environment and Planning and the Centre for the Study of the Environment and the Sea (available at: http://uaonline.ua.pt/pub/detail.asp?lg=pt&c=45245).

PwC previously produced studies of the carbon footprint of every Corticeira Amorim Business Unit (BU), independently verified by Deloitte, which concluded that Amorim’s business activity results in carbon sequestration of more than 2 million tons per year - more than 15 times the amount of greenhouse gas emitted across its entire value chain.

Corticeira Amorim has been committed to a Circular Economy strategy since 1963 when an industrial unit for the production of cork grains and agglomerates was formed with the objective of transforming 70% of the waste generated from the manufacture of cork stoppers.

The independently confirmed negative carbon footprint of Neutrocork is aligned with Amorim’s wider strategy to promote cork as one of the world’s most amazing and sustainable natural products.